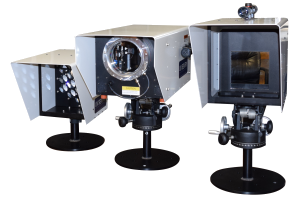

Model: UV Sentry

Manufacturer: Cerex

The Cerex UV Sentry offers high performance, time resolved monitoring of a variety of regulated gases. With part per trillion minimum detection limits for benzene the UV Sentry allows regulatory compliance for SCAQMD Rule 1180 and BAAQMD Rule 12-15 BTEX monitoring. It also represents a stand-alone solution for alternative MACT compliance for USEPA Method 325 refinery fenceline benzene monitoring.

A true multi-gas analyzer solution, fielded units measure acrolein, ammonia, BTEX, butadiene, chlorine, formaldehyde, naphthalene, nitric oxide, nitrogen dioxide, phenol, styrene, sulfur dioxide and more. Path lengths tested to 1300 meters offer gap-less monitoring coverage with hands-off reliability.

Features

The Cerex UV Sentry Open Path Multi-gas Analyzer sets the industry standard for time-resolved, gap-less fugitive emissions and chemical emergency monitoring across fencelines, around process units and around tank farms.

The most cost effective perimeter & fenceline monitoring solution…

Multi-gas monitoring over linear distances exceeding 1000 meters, minimal infrastructure requirements and direct integration with existing factory management systems provide cost effective installation. Low consumables, field proven service life, inherent calibration and “hands off” operation provide low cost of ownership.

Offers part per trillion real time detection limits for early warning of fugitive emissions…

Part per trillion to low part per billion detection limits and wide dynamic ranges enhance early leak detection and release characterization. Concentrations of gases below the detection thresholds of traditional sensor arrays are readily detectable with the UV Sentry analyzer. Early detection translates into quicker response times, reduced environmental impact, decreased plant downtime and reduced exposure of site personnel and the community.

Of individual species of prolific hazardous air pollutants…

UV Sentry analyzers quantify individual species of toxic gases within complex mixtures using standard CLS analysis coupled with proprietary real time spectral analysis routines. Monitoring performance is immune to interference from water vapor and the UV Sentry analyzer cannot be poisoned. Typical accuracy and precision at FAT are 2.5% and 3.0% of reading respectively.

Species include gases commonly of concern in Chemical Manufacturing, Refinery Operations, Acid Plant Operations and Ore Processing, Concrete Manufacturing, Mining Operations, Environmental Remediation and More…

For EPA 40 CFR 63.658, BAAQMD Rule 12-15 and SCAQMD Rule 1180 Compliance

As a stand alone analyzer for BTEX, Acrolein, Formaldehyde, SO2, Styrene… or as a component within a larger analyzer array including the Cerex AirSentry FTIR for Ammonia, Alkanes, Formaldehyde, HF, HCN, etc… Cerex offers comprehensive monitoring compliance solutions for Federal, State and Regional monitoring requirements.

With seamless integration into SAFER Systems chemical emergency management software

For facilities using SAFER Systems’ emergency response software the UV Sentry analyzer integrates seamlessly. SAFER’s patented software is used in conjunction with Cerex hardware in several different ways; pre-emergency for preparation and training, during an emergency for emergency response, and post-emergency for future event mitigation, regulatory reporting, and litigation response. The complete solution utilizes live streaming data from on-site weather stations and Cerex gas detection sensors to generate a visualized model of the chemical plumes or soot clouds released during an emergency. The models automatically update as weather/sensor data changes so that emergency response teams know who or what will be impacted by the emergency (whether on-site or off-site), who needs to be evacuated or shelter in place, and how long the event will last. In the case of highly flammable chemicals, the models show where the combustion particulates will be deposited as well as the chemical composition of the soot clouds. All of the models and data are archived so they can be used for post-emergency analysis of the event, in response to odor complaints and litigation, and for reporting to regulatory agencies when needed. Not only can response teams use pre-defined scenarios prior to an emergency, but they can also use the archived data and models to base their emergency drills and training on actual events that may have occurred.