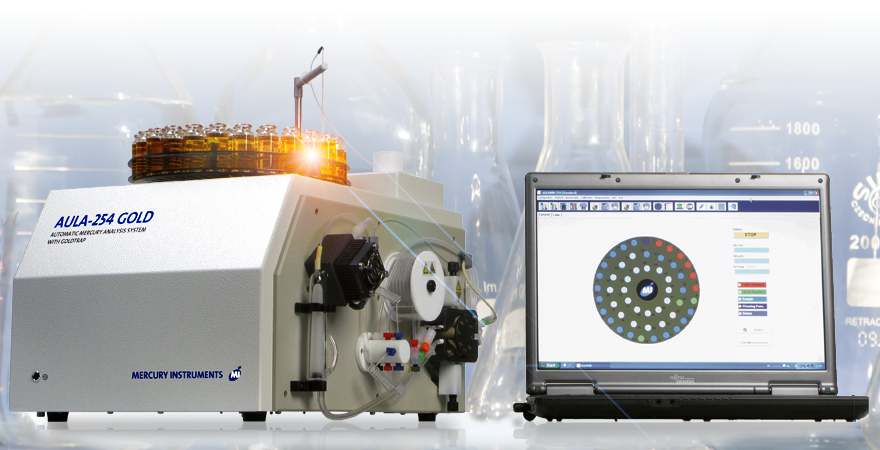

Model: Aula 254 Gold

Manufacturer: Mercury Instruments/Envea

The AULA 254 Gold is used for fully automatic determination of mercury traces in liquid samples and sample digests. The instrument carries out routine analysis: sample after sample following exactly the preselected procedure thus increasing efficiency and productivity of your lab.

Fully automated flow analysis system

Proven and reliable detection method: cold vapor atomic absorption (CVAAS)

Integrated GoldTrap for a maximum of sensitivity of <1 ng/l

Features

Reliable and proven measurement method:

The working principle of the system is based on the continuous flow method. First the mercury contained in the sample is transformed into the elemental state by addition of a reducing agent to the sample flow. In a cross-flow reactor the mercury is stripped with a gas stream and carried into the optical cell which is made entirely of fused silica. There the quantitative determination of mercury is obtained by measuring UV absorption at a wavelength of 253,7 nm at room temperature. This analytical technique is commonly known as cold vapor atomic absorption spectrometry (CVAAS), a method that has proved to be extremely sensitive and selective for many years.

Optimized mercury detection techniques

In contrast to a typical multi-element AAS the AULA is specially designed for mercury determination. This allows top performance in analytical applications. The use of a highly stable low-pressure electrodeless mercury discharge lamp (EDL) in connection with the latest UV detector techniques result in excellent baseline stability and low detection limits.

Measurements of up to 20 calibration standards and up to 53 samples and check standards are carried out fully automatically. Standards and samples are filled into 10 ml glass vials and positioned on the auto-sampler turntable. Reagent solution (for example tin-(II)-chloride) and rinse solution (reagent water) are filled in the corresponding glass tanks. Then the stripping gas flow is adjusted and measurement is started by a keystroke.

The measurement cycle can be interrupted at any time by the operator for selecting any sample to be measured next. Readings and instrument status are displayed in real-time on the screen.

The stability of the baseline is checked prior to each measurement and the zero point is adjusted automatically. The typical zero drift during a measurement is below 0.0001 absorbance units.